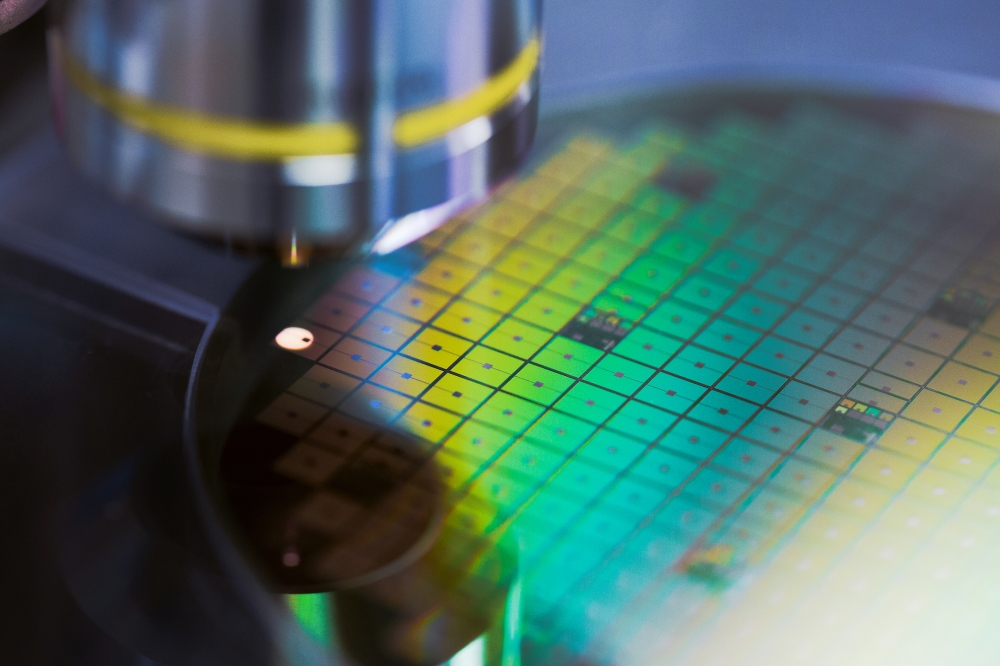

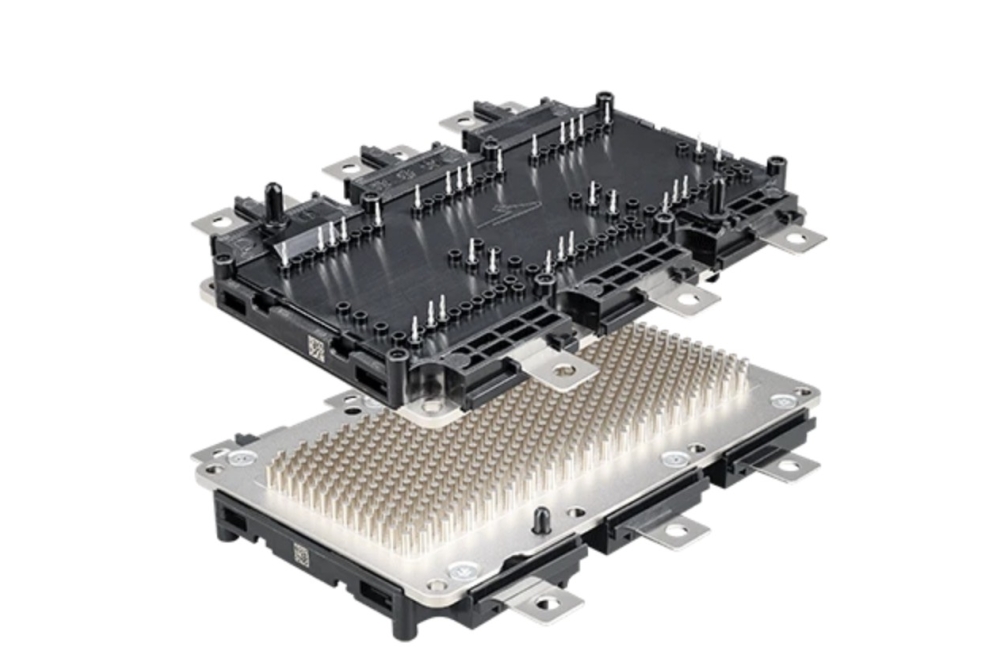

Wolfspeed launches 1200V SiC six-pack modules

Wolfspeed has announced its new 1200V SiC six-pack power modules or high-power inverters.

By combining the latest advanced Gen 4 SiC MOSFET technology and innovative packaging, the company says its modules can deliver three times more power cycling capability at operating temperature than competing solutions, and 15 percent higher inverter current capability in an industry-standard footprint.

"These modules provide a means for electric mobility OEMs to take a quantum leap forward in technology," said Cengiz Balkas, Wolfspeed chief business officer. "We took proven, well-rounded switching performance made possible with our Gen 4 MOSFETs and turned further knobs with our YM package to greatly improve power cycling – one of the biggest performance hurdles a power designer can face. In doing so, we're delivering the reliability, efficiency, and power density that heavy-duty, construction and agricultural vehicles demand.”

The new modules incorporate state-of-the-art packaging technology including sintered die attach, epoxy encapsulant material, and copper clip interconnects, enabling 3X more power cycles than best-in-class competitor devices in the same footprint. In this new white paper learn more about Wolfspeed's power cycling and lifetime modeling approach.

The modules achieve a 22 percent RDS(ON) improvement at 125°C compared to the previous generation, while reducing turn-on energy (EON) by approximately 60 percent across operating temperatures. Additionally, the soft-body diode enables 30 percent lower switching losses and 50 percent lower VDS overshoot during reverse recovery compared to previous generation.

The modules' industry-standard packaging enables seamless adoption without complex redesign, serving as a direct replacement for IGBT solutions in existing system architectures. With simpler assembly requirements, the modules eliminate the need for power terminal laser welding and complex coldplate mounting while maintaining compatibility with traditional power ecosystems including capacitors, cooling solutions, gate drivers, and current sensors.

“These modules' enhanced power cycling capabilities and efficiency translate directly to reduced maintenance costs, extended vehicle operational life, and improved energy efficiency - addressing critical concerns for fleet operators and OEMs focused on total cost of ownership and sustainability goals,” – notes Guy Moxey, VP and general manager for Industrial and Energy.

The 1200V SiC six-pack power modules are now available for customer sampling with full availability at distributors in early 2026.