Enhancing MMC VSC HVDC system performance with press-pack IGBT technology

By adopting Press-Pack IGBTs, operators can significantly reduce component-level failure risks while improving overall system efficiency and lifetime economics – a decisive advantage in today’s utility-scale energy infrastructure.

BY Dr Sajad Ansari, SENIOR Power Electronics Applications Engineer, Dynex Semiconductor

HVDC technology facilitates the transmission of large amounts of power over long distances using direct current. There are two primary HVDC technologies: Line-Commutated Converters (LCC) based on thyristors, and self-commutated Voltage Source Converters (VSC) based on IGBTs.

LCC-based HVDC systems consume reactive power and require large AC filters, necessitating connection to a strong power grid. Reversing power flow also requires changing the DC voltage polarity, meaning all terminals must switch simultaneously, making them unsuitable for multi-terminal HVDC networks. They are therefore mainly used for high-power, long-distance, point-to-point links where power flows predominantly in one direction, such as bulk transmission from remote generation sites to major consumption centres.

MMC-based VSC-HVDC systems produce very low harmonic distortion, requiring only modest high-frequency AC filters. They can continuously generate or absorb reactive power, interconnect asynchronous grids, and maintain voltage even on very weak or “dead” networks. Unlike LCC, reversing power flow in VSC is achieved by changing the current direction while keeping the DC voltage polarity constant, which makes multi-terminal and meshed HVDC networks practical.

These attributes make VSC technology the preferred choice for some renewable generation—particularly offshore wind farms – and for providing flexible grid interconnections.

MMC-based VSC-HVDC systems, as shown in Figure. 1, require various power semiconductor devices – including IGBT and FRD modules – to perform voltage switching. Bypass thyristors may also be used to reduce current stress on the modules during DC-side faults by providing a controlled bypass.

Figure 1. MMC VSC-HVDC Systems.

These systems demand semiconductor devices that are not only high-performing, but also robust, maintainable, and space-efficient. In this context, the Press-Pack IGBT (PPI) has emerged as the preferred solution over conventional encapsulated IGBTs with bond wires—particularly in high-reliability, mission-critical HVDC applications.

This article discusses the mechanical, electrical, and operational advantages of PPIs. It highlights how their integration into spring-loaded stacks, ease of maintenance, and superior thermal management and fault-tolerant behaviour contribute to enhanced system robustness, lower lifecycle costs, and improved overall efficiency.

Introduction to IGBT Packaging in HVDC

In VSC HVDC applications, where IGBT modules are subjected to extreme electrical and thermal stress, two primary packaging types are commonly used, as shown in Figure. 2:

⬤ Encapsulated (Plastic) IGBT Modules:

Fully packaged modules that rely on bond wires, PCB, and solder layers for electrical connections between the chips and terminals. They require external gate and auxiliary wiring, as well as robust mounting and thermal interface strategies.

⬤ Press-Pack IGBT Modules (PPI):

Metallurgically bonded, pressure-contact devices that enable direct electrical and thermal connection under uniform clamping force and are optimised for series connection.

While both technologies are capable of handling high voltage and current demands, PPIs offer distinctive mechanical and system-level advantages — including superior thermal performance, ease of maintenance, and improved fault tolerance — which are becoming increasingly important in modern VSC HVDC topologies.

Figure 2. Packaging solutions for IGBT modules in VSC HVDC applications.

(a) Encapsulated IGBT module. (b) Press-Pack IGBT module.

4.1 Structural and Assembly Advantages of Press-Pack IGBTs

Encapsulated IGBT modules may seem easier to mount, as they typically require only screwing down. However, each replacement still involves wiring, bolting, and applying thermal interface materials, which can be time-consuming.

PPIs are designed for direct press-contact operation, eliminating the need for thermal interface materials and extensive external wiring. PPIs can be assembled into spring-loaded stacks, which ensure uniform pressure distribution and consistent electrical and thermal contact across all devices. This modular and clamped approach not only enhances system integration but also supports rapid configuration and field replaceability, making PPIs particularly well-suited for high-reliability HVDC systems where downtime must be minimised.

4.2 Maintenance and System Uptime Benefits

To support maintainability in mission-critical HVDC systems, PPIs offer several practical advantages over encapsulated IGBT modules, particularly in the areas of field serviceability and condition monitoring.

Figure 3. Trench-gate vs planar-gate for PPIs.

These are detailed in the following subsections:

4.2.1 Field replaceability

⬤ PPIs allow non-destructive disassembly and individual device replacement within a clamped stack, without disturbing thermal interfaces or mounting assemblies.

⬤ In contrast, replacing an encapsulated module typically requires unbolting the unit, cleaning and reapplying thermal paste, and remaking all electrical and cooling connections — resulting in a longer maintenance time.

4.2.2 Visual inspection and predictive maintenance

⬤ PPIs allow visual access to contact surfaces and support contact resistance monitoring, enabling more predictive maintenance strategies.

⬤ PPIs integrate well with intelligent stack assemblies featuring real-time health diagnostics.

4.3 Robustness and Reliability

Beyond maintainability, the intrinsic structural advantages of PPIs also translate into superior fault tolerance and operational reliability.

The following sections outline key benefits related to short-circuit performance and endurance under demanding thermal cycling conditions:

4.3.1 Enhanced surge current capability

⬤ Since PPIs do not use bond wires, they tend to be more robust under surge current conditions.

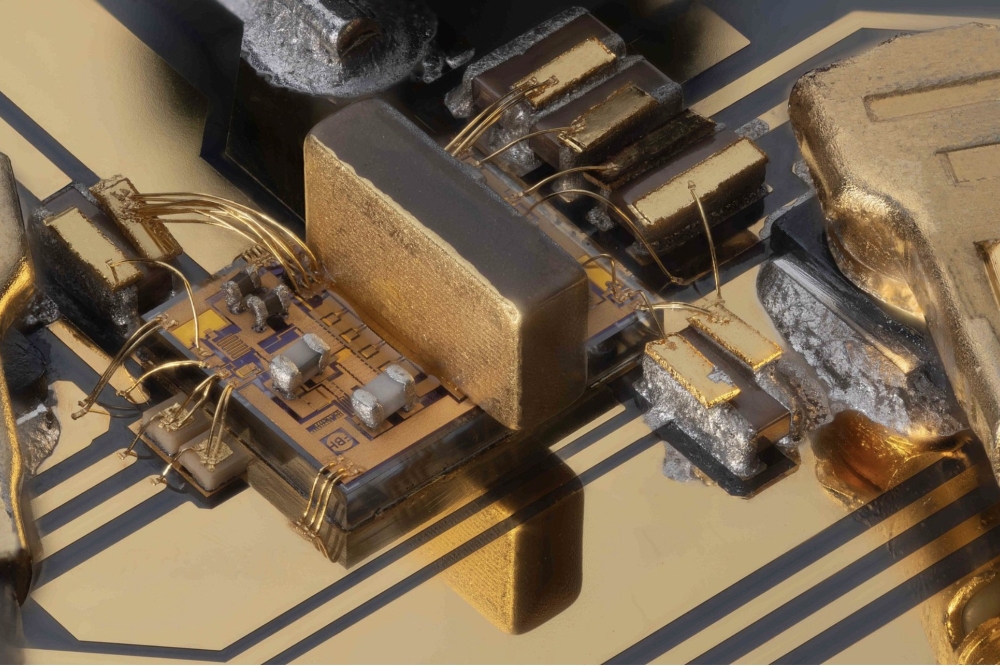

Figure 4. PPI 1.0 packaging steps. Figure 4. PPI 1.0 packaging steps

4.3.2 Enhanced short-circuit capability

⬤ Press-pack devices are designed to fail short in most cases, enabling controlled bypass and system continuity.

⬤ Encapsulated IGBTs may fail open-circuit, leading to converter-level outages or loss of redundancy.

4.3.3 Thermal cycling endurance

⬤ Unlike encapsulated IGBT modules with bond wires, PPIs eliminate internal wire bonds – a common point of failure under cyclic loading.

This design offers higher mechanical integrity and longer operational lifetimes, particularly under repetitive pulsed loads and fault conditions.

⬤ Such reliability is critical for offshore wind power and its connection to the grid via remote HVDC systems, where frequent load variations are typical.

Figure 5. PPI 2.0 packaging steps.

4.4 Efficiency and System-Level Cost Impact

Alongside reliability and maintainability, system-level efficiency and cost are critical considerations in HVDC applications. The following sections compare PPIs and encapsulated IGBTs in terms of losses and overall lifecycle economics:

4.4.1 Efficiency comparison

⬤ PPIs benefit from slightly lower thermal impedance, which helps limit temperature rise. This in turn keeps the on-state voltage lower, directly reducing conduction losses and stress under high-load operation.

⬤ The stack’s intrinsic symmetry helps series-connected PPIs share voltage more evenly, enabling simpler active-balancing networks and reducing their power loss.

4.4.2 Cost comparison

Cost-wise, encapsulated IGBT modules are cheaper upfront due to standardised mass production and simpler mounting. However, PPIs, while more expensive initially, tend to offer lower long-term maintenance costs. Their robust, bond-wire-free design provides longer service life, superior thermal endurance, and fewer replacements.

Additionally, their lower losses can reduce operational energy costs — all contributing to a potentially lower total cost of ownership in demanding HVDC applications.

Dynex PPI Advancement for HVDC Applications

Dynex offers a comprehensive portfolio of high-voltage PPI module options specifically designed for HVDC VSC applications, with voltage ratings from 4.5 kV to 6.5 kV and current capabilities up to 5000 A.

Figure 6. Selected test results for 6.5kV/2kA PPI 2.0. (a) RBSOA. (b) RRSOA. (c) SCSOA.

5.1 Chip advancement

Dynex, in collaboration with CRRC, has recently released the 5th generation of Dynex IGBT chip technology for its PPI product line, marking a significant advancement in device performance and robustness. As shown in Figure. 3, this generation adopts Trench-Gate architecture, delivering superior current density of up to 200 A/cm² compared to the previous Planar-Gate design, which offered 160 A/cm².

The integration of carrier-enhanced injection and Field Stop technology enables better control of the electric field within the device, leading to lower switching and conduction losses. These advancements make the latest Dynex 5th-generation TMOS chips now available in press-pack format – ideal for demanding HVDC applications. With higher efficiency, improved thermal performance, and increased ruggedness, these new-generation chips solidify Dynex’s position in delivering reliable and high-performance semiconductor solutions for next-generation power transmission systems.

5.2 Packaging advancement

Historically, Dynex—like many manufacturers – used ‘Hockey Puck style’ (round-shaped) Press-Pack IGBT designs, which were standard in early HVDC applications. However, as performance demands increased and packaging efficiency became more critical, the design transitioned toward a square-shaped format. This shift allowed for better utilisation of area, improved current distribution, and more efficient heat spreading, particularly beneficial for high-current, high-voltage systems.

Dynex’s first-generation Press-Pack IGBT (PPI 1.0), developed with CRRC Semiconductor, laid the foundation for robust HVDC device design. As shown in Figure. 4, this generation features a sealed ceramic casing, double-sided Ag sintering, and a flexible spring-loaded contact system to ensure uniform pressure distribution across all subunits. The modular design allows for a variable number of subunits, enhancing design flexibility and enabling thermal and electrical balancing within the device. With a maximum voltage and current rating of 4500 V and 3000 A, Press-Pack 1.0 provided an exceptionally reliable solution for early HVDC and flexible DC grid systems. This foundational platform directly influenced the development of the more advanced Press-Pack 2.0, incorporating many of its proven mechanical principles while introducing significant thermal and electrical enhancements.

To support the next generation of high-power and high-reliability HVDC systems, Dynex has introduced Press-Pack IGBT 2.0 (PPI 2.0) – a significant upgrade over traditional press-pack designs. As shown in Figure. 5, this new generation incorporates several advanced features, including flexible spring-loaded pressing, double-sided chip soldering, higher operating junction temperature, and a more thermally efficient layout

The new design achieves over 20% reduction in thermal resistance, allowing for improved cooling and higher power density. Additionally, the devices have successfully passed destructive fault condition testing (at 24 mF and 4400 V), confirming robustness. Furthermore, the weight has been reduced by 25.2% compared with PPI 1.0.

With maximum ratings of 4500 V/5000 A and 6500 V/3000 A, PPI 2.0 products are well-suited for mission-critical HVDC applications, where performance, fault tolerance, and maintainability are essential.

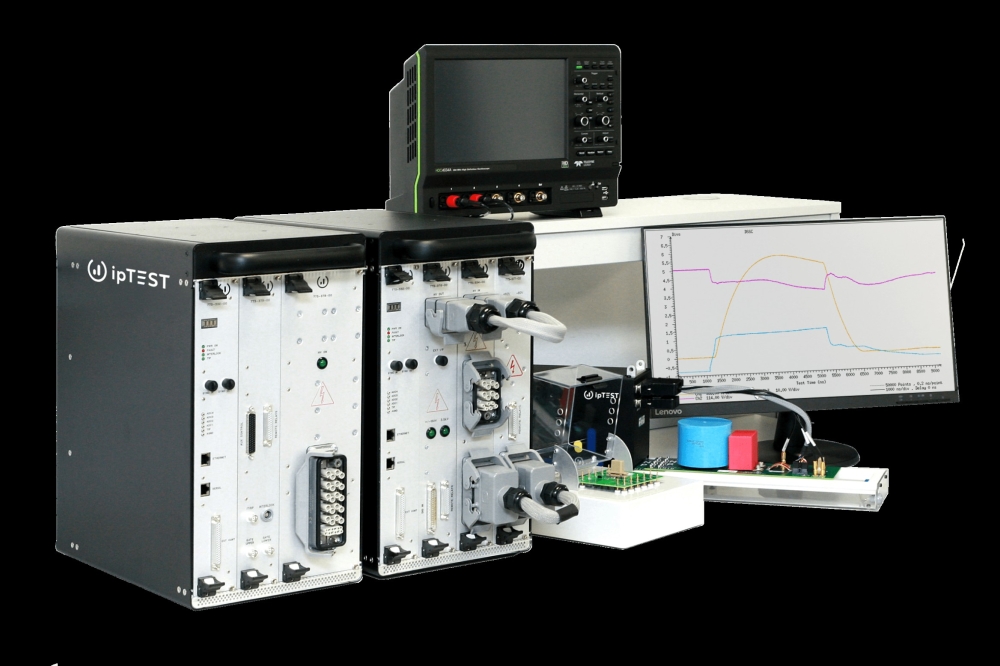

5.3 Validation and Standards

To ensure the reliability, consistency, and performance of its PPIs, Dynex – through its collaboration with CRRC Semiconductor – employs a comprehensive suite of validation and test procedures covering all stages of the product lifecycle. A few of these tests include:

⬤ Chip-level defect detection and probe testing.

⬤ High-temperature static and dynamic testing

⬤ Safe operating area (SOA) testing

⬤ Electrical insulation and integrated parameter checks

⬤ Full thermal resistance measurements, validated using JESD51-14-2010 for junction-to-case thermal path analysis

Dynex PPIs are tested across voltage ranges from 4500 V to 6500 V, with routine tests and reliability assessments conducted at both chip and module levels. All testing aligns with relevant international standards, including IEC 60747-9 for IGBT devices. This rigorous approach ensures that each device meets the high reliability and safety standards demanded by HVDC systems and other mission-critical power applications.

In addition to rigorous routine testing, Dynex’s PPIs have undergone comprehensive SOA validation to ensure robust performance under fault and extreme operating conditions.

As shown in Fig. 6, the 6.5kV/2kA PPI demonstrate excellent Reverse Biased SOA (RBSOA), safely turning off at 4.4 kV and 6000 A, exceeding typical test requirements.

The Reverse Recovery SOA (RRSOA) confirms that the freewheeling diode structure can withstand very high energy dissipation during reverse recovery. Furthermore, the Short-Circuit SOA (SCSOA) testing shows the device enduring 15 µs of short-circuit duration at 4.4 kV, well above the industry requirement of around 10 µs.

These results confirm that the devices possess high ruggedness, with stable operation across a wide range of

stress conditions. Together with compliance to IEC 60747-9 and thermal validation via JESD51-14-2010, these SOA waveforms provide strong evidence of the devices’ reliability for HVDC and other mission-critical applications.

Conclusion

In the transition toward more flexible and resilient HVDC networks, PPIs offer a compelling alternative to encapsulated IGBT modules. Their inherent modularity, superior reliability, and service-friendly design make them especially well-suited for modern VSC systems that require high performance with minimal downtime and reduced operational complexity.

By adopting Press-Pack IGBTs, operators can significantly reduce component-level failure risks while improving overall system efficiency and lifetime economics — a decisive advantage in today’s utility-scale energy infrastructure.

Dynex, in collaboration with CRRC, has developed a wide range of power semiconductor devices tailored for HVDC systems. This article has discussed some of the recent advancements and features of Dynex Press-Pack IGBT technology, including:

⬤ Hermetic packaging for enhanced reliability in harsh environments

⬤ Both square and round housing options

⬤ Double-sided Ag sintering for improved thermal and mechanical performance

⬤ Flexible spring pressure design

⬤ Excellent surge handling and short-circuit tolerance

⬤ Short-Circuit Failure Mode (SCFM) with extended lifetime

⬤ Optional integration with anti-parallel diodes

⬤ Low conduction losses enabled by advanced trench IGBT chips

⬤ High voltage and current ratings for demanding applications.

.