SuperQ MOSFET sets new safety level for HV batteries

iDEAL Semiconductor has announced the availability of its SuperQ MOSFET technology, purpose-built to solve the critical safety and efficiency trade-off in high-voltage (72V and higher) battery management systems (BMS).

The company says its new platform sets an industry benchmark for short-circuit withstand capability (SCWC), the most vital safety metric for the BMS discharge switch. Maintaining ultra-low RDS(on) of 2.5mΩ minimises conduction losses, extending battery run-time and reducing thermal management needs.

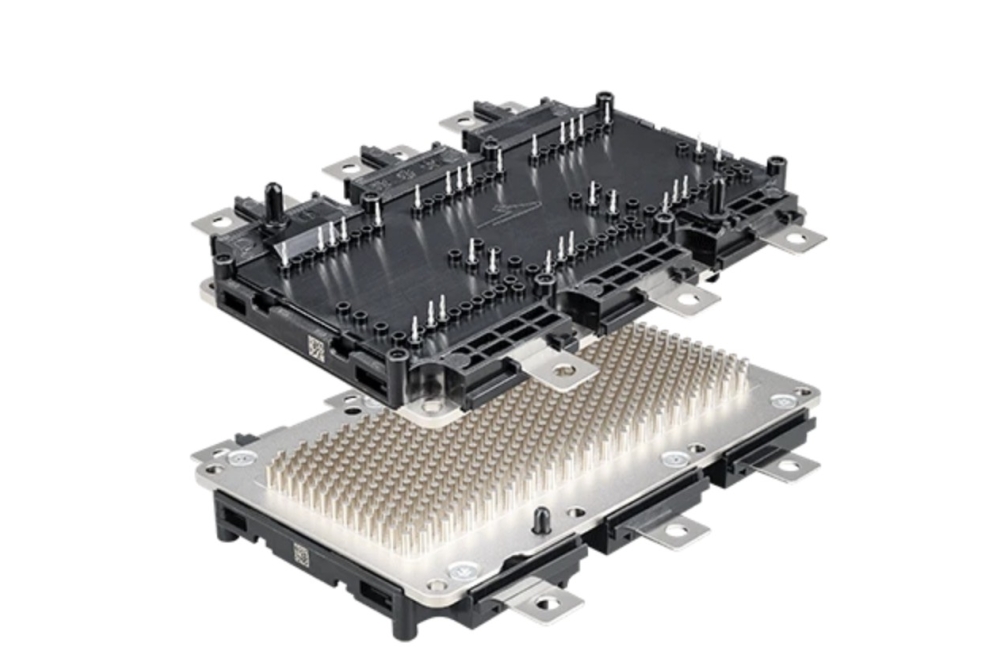

The proliferation of high-voltage battery packs in e-mobility, drones and professional power tools introduces a high-stakes challenge: protecting against catastrophic failure during external short-circuit events, where currents can spike into the thousands of amps. The discharge MOSFET is the single component responsible for isolating the battery pack under these extreme conditions.

"In high-energy packs, robustness is non-negotiable. Traditional MOSFET designs are forced to compromise between achieving ultra-low RDS(on) for efficiency and the structural integrity needed to survive a massive short-circuit current," said Phil Rutter VP of design at iDEAL Semiconductor. "The SuperQ platform eliminates this compromise. Our proprietary cell structure delivers the market's lowest on-resistance alongside a safety margin that is simply unmatched, giving designers the confidence to build smaller, more reliable, and lower-cost battery systems."

iDEAL’s internal testing demonstrated that the SuperQ device exhibited a 1.4 times higher short-circuit failure capability than its closest competitor. This performance is achieved through a proprietary cell structure featuring a wider conduction region that maximises power density and structural integrity under extreme stress, according to the company.

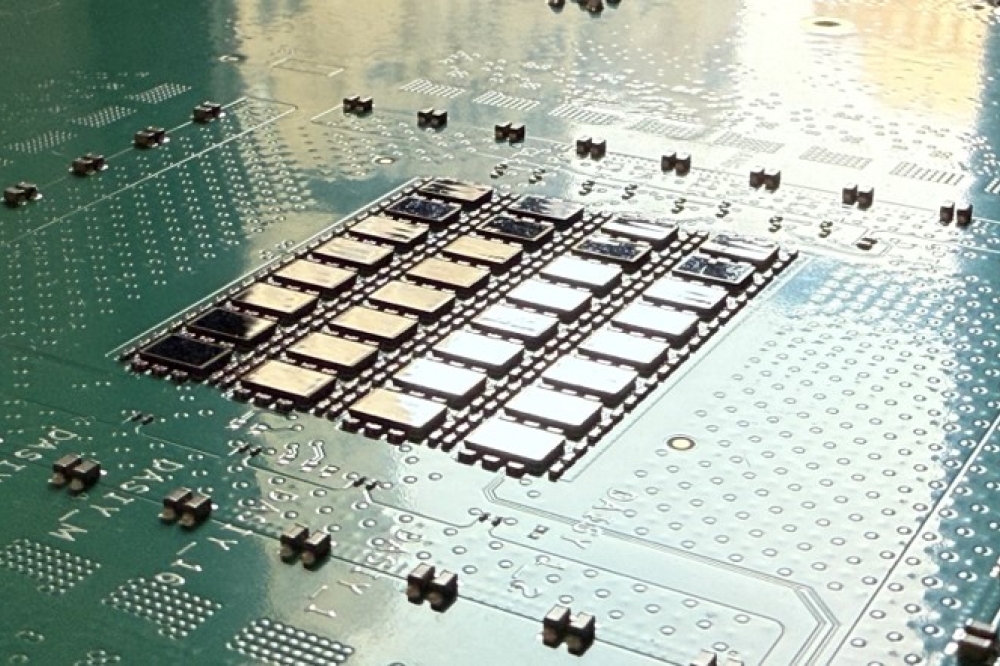

The SuperQ portfolio is available now with devices up to 200V, providing solutions for battery platforms ranging from 72V to over 144V.