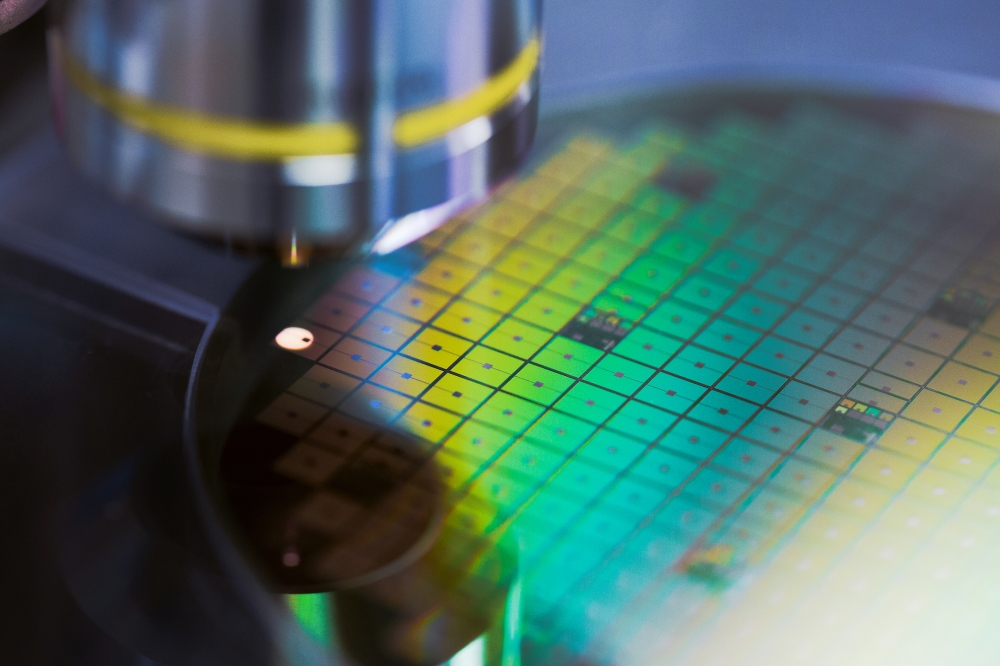

X-FAB speeds time-to-market for SiC MOSFET solutions

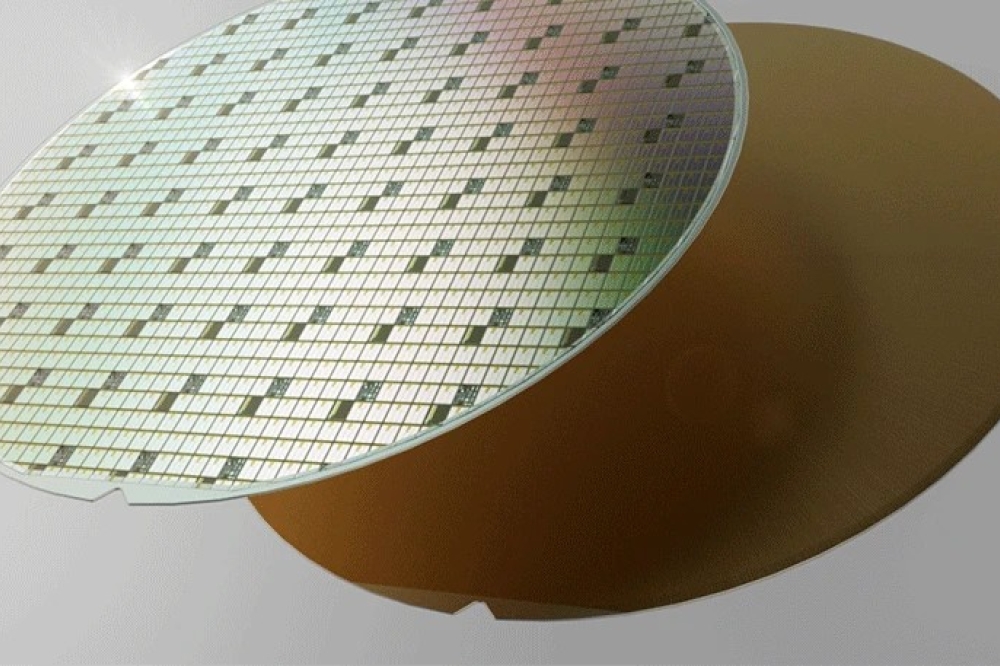

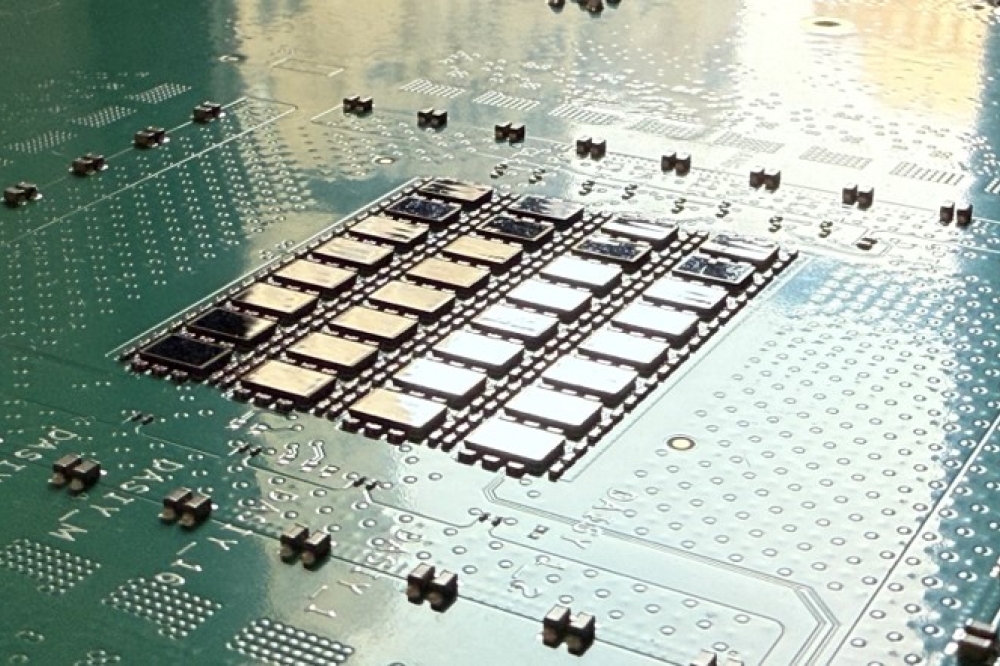

Specialty foundry X-FAB is offering easy access to a standardised yet flexible set of SiC process technologies that accelerate the development of advanced power devices.

From rapid prototyping to full production, the modular and scalable XbloX platform is said to help SiC device developers to expedite engineering assessments and technology release, with production starts achieved up to nine months faster than traditional methods.

The XbloX WBG discrete foundry model has two major benefits, according to the company. Firstly, X-FAB takes on process development activities with the introduction of a Process Installation Kit (PIK), where design and implant recipes provide key differentiators. Secondly, the use of XbloX ensures wafer manufacturing at X-FAB becomes a highly scalable activity in line with application requirements, differing considerably from the less scalable production provided by a traditional foundry model for customer-specific SiC technologies.

“Thanks to a PIK, qualified SiC process development modules, and an automated onboarding process, customers need do little more than access our global hotline for support on block selection and deployment,” explains Brian Throneberry, business director SiC Foundry at X-FAB.

“We have robust rules in place to help guide design, mask tooling, engagement, and so on. Once the selection is finalised, XbloX automatically generates the process flow, which subsequently integrates quality systems, business functions, and commercial aspects for the customer. It’s a highly expedited way of providing customers with the flexibility required to build custom SiC MOSFET technologies at an accelerated rate.”